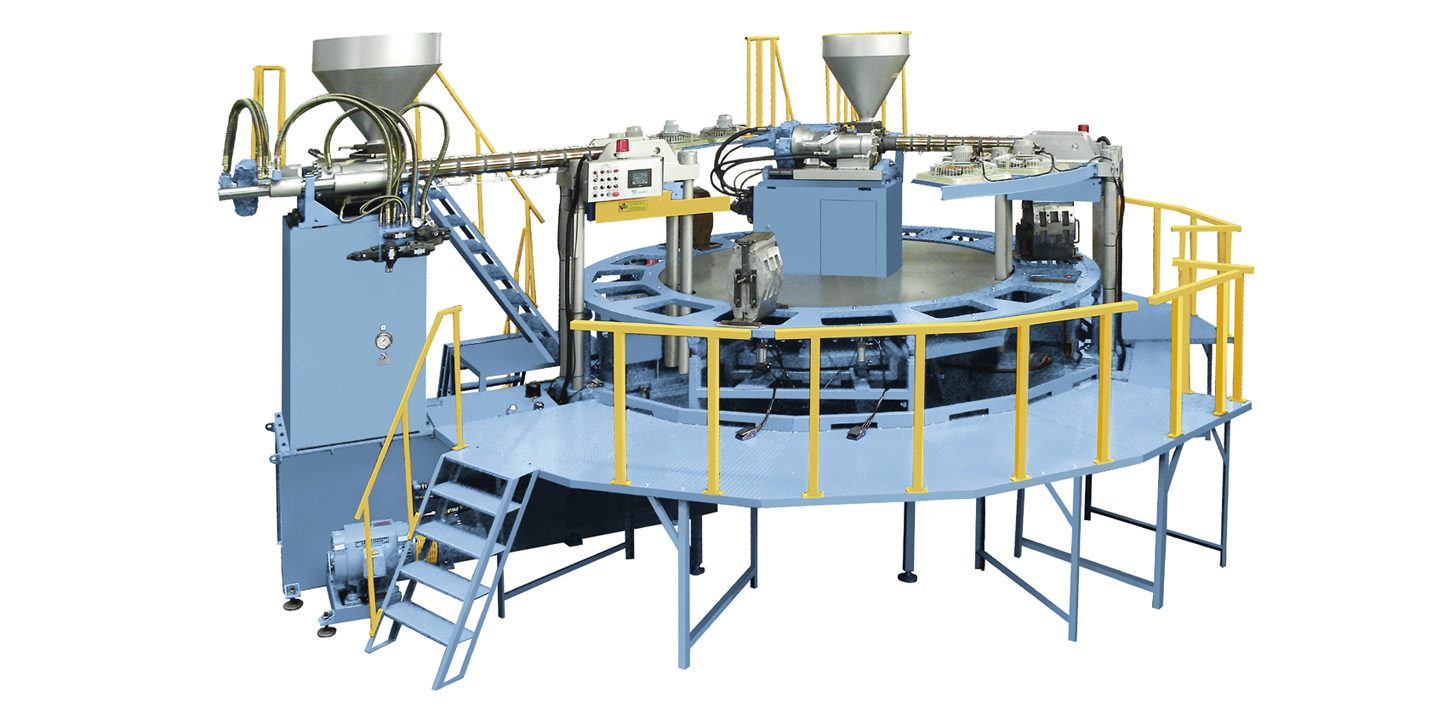

Automatic Rotary One Color/Two Color Boots Direct Injection Molding Machine

1. Equipped with the full-auto in feed volume control system in each station. Easy to operate and enhance production flexibility.

2. The oil pressure circuit design ready for mold close will shorten the cycle time and upgrade productivity.

3. As the feeding is controlled by back pressure, it is capable of adjusting foaming density of raw material.

4. The adopted movable ejection unit controlled by oil pressure makes it easier to clear away the material.

5. Pressure switch assures the locking strength by mold lock system for far better product.

6. The emergent safety button is to safeguard the operational safety.

7. The turn table may run reversibly in case of emergency to eliminate the abnormality and upkeep the safety operation.

8. Furnished with mold air-blowing device, the finished products may be de-molded easily.

9. Products: specially designated to manufacture different height full plastic boots or shoes.10. Material: suitable for all kinds of thermoplastic raw material, foaming or non-foaming, such as PVC and TPR.

Reviews

There are no reviews yet.