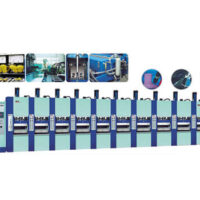

Automatic Rotary Plastic Shoe Direct Injection Molding Machine

1. Unique design for mold opening. While opening mold, the upper cover of mold holder can move 30mm up vertically then tilt open to 450. The operation is very smooth and rigid.

2. Special design “conjugate cam” index mechanism is used for transmission system to rotate table, which ensures rapid rotation, accurate positioning, and long duration.

3. Strong C-type mainframe is designated for functioning mold cooling device. Cooling system is very efficient.

4. Proportional pressure and flow rate control hydraulic circuit are used in system and match up with monitor electric control system. It controls individual injection pressure and speed of each work station.

5. Excellent arrangements in matching up hydraulic circuit and electric control shorten the waiting time and increase productivity.

6. Special design of C-type mold clamping cylinder together with universal joint mechanism ensures the balance of mold clamping force and increases lifetime of mold as well as cylinder.

7. One set of TK-880 can substitute for five sets of traditional horizontal injection molding machine to save investment of equipment, electric power consumption, and labor cost; in the meantime, to increase production and profit.

8. Products : Applicable to manufacturing various plastic products and outsole…etc

9. Material : Suitable for using foaming or non-foaming thermoplastic material such as PVC, TPR…etc.

Reviews

There are no reviews yet.