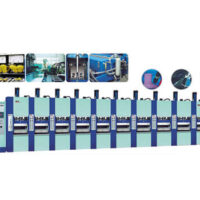

Rotary Eva Hot & Cold Molding Machine

Less Manpower & Less Energy & Higher Productivity

1. Mold bracket and limit switch installed to prevent the mold from collision in order to extend the lifespan of the mold.

2. Disc rotates with high production rational speed to increase the productivity.

3. Machine is activated by both hand confirmation,which ensures the safety of the operator.

4. Temperature for upper and lower mold can be set independently which increases the products Defect-free rate.

5. Exchange mold automatically to save manpower.

6. The operator dose not have to walk around,which reduces tiredness.

Reviews

There are no reviews yet.