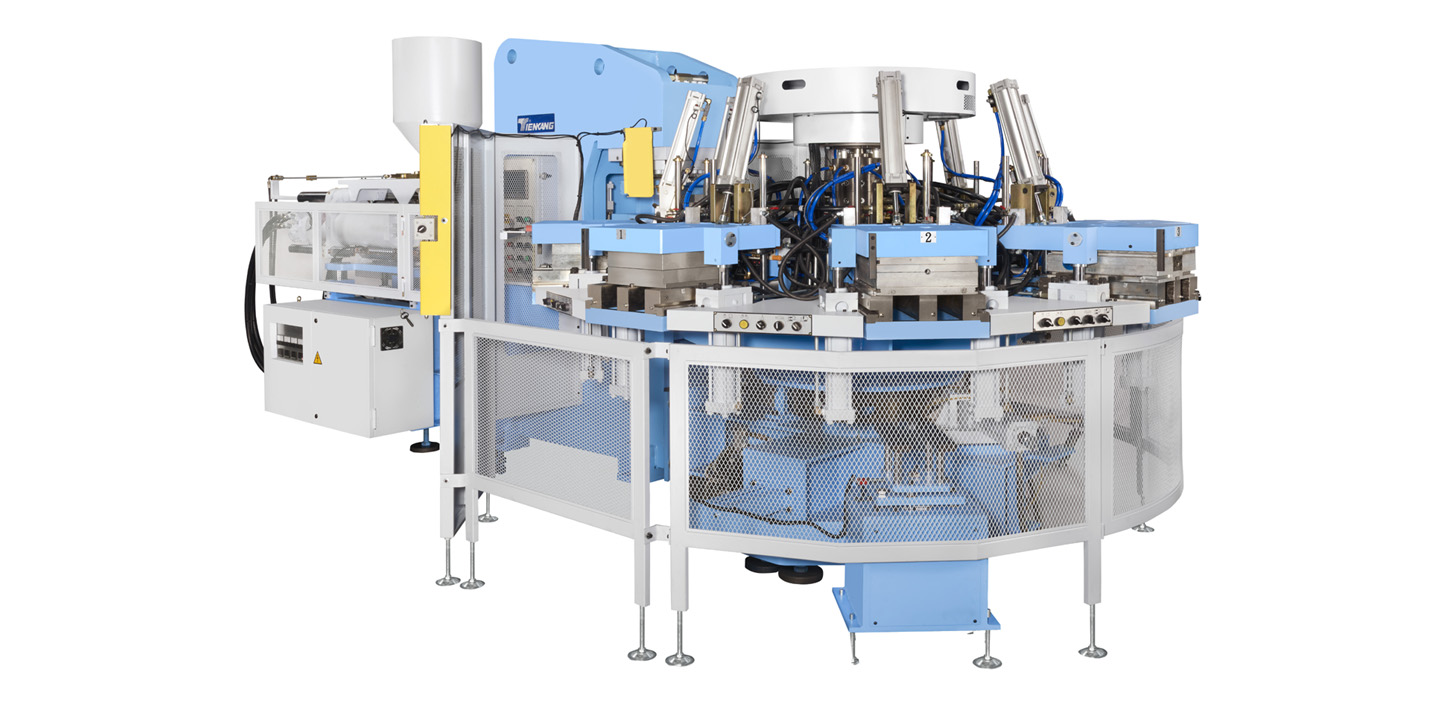

TK-832 is specialized in making various kinds of PVC or TPR unit soles, especially using different sole molds with different nozzle height together on production.

1. Automatic mold opening system,with ejectors and slide out device.

2. Open space design of C type structure will be more convenient to shorten maintenance time.

3. Equipped with compact design of hydraulic control loop to make the rotation smooth and fast.

4. Flexible injector adjustment station by station. For sole with different thickness.

5. Equipped with high level potentiometer for precision injection volume control to increase parts quality.

6. Equidpped with servo motors for power saving.

Reviews

There are no reviews yet.