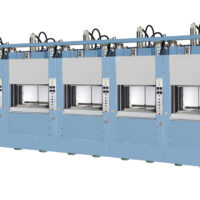

Thermoplastic Multi-color Static Injection Molding Machine

Mold Carrier Unit

1. Mold thickness automatically compensated hydraulic clamping system.

2. Three-position (0°-90°) mold rotating head, providing multi-mode production capability for single color and two-color unit soles.

3. Unique rotating head positioning mechanism, providing precise and fast mold positioning.

4. Upper and bottom molds ejector units for easy, fast and distortion free sole removal.

5. Automatic sliding unit for flexible and easy sole collection and for easy insertion parts placement.

6. Separate blowing system on three faces rotating head and bottom mold plate, providing easy soles and sprue removal.

7. Suitable for molding TPU in multi-color unit soles by injection system.

Feeding Unit

1. Electric motor driven injection point height adjustment system, suitable for different size of molds.

2. Adjustment or injection point with horizontal leveling, no material heap at channel or extruders.

3. Precise barrel temperature control with P.I.D. control system.

4. It is easy and fast for material changing with less waste.

Electric Control System

1. With self-diagnosis analysis system, current status of machine operation can be monitored to insure smoothly production.

2. Providing with work file records, processing parameters for different molds can be saved with individual files, production is more efficient.

3. Every extruder is with independent nozzle, material flow is not interfered, colors are not mingled, outsole colors are more clear.

Reviews

There are no reviews yet.